We are a one stop shop of wear resistant mateirals for complete wear solutions.

Products

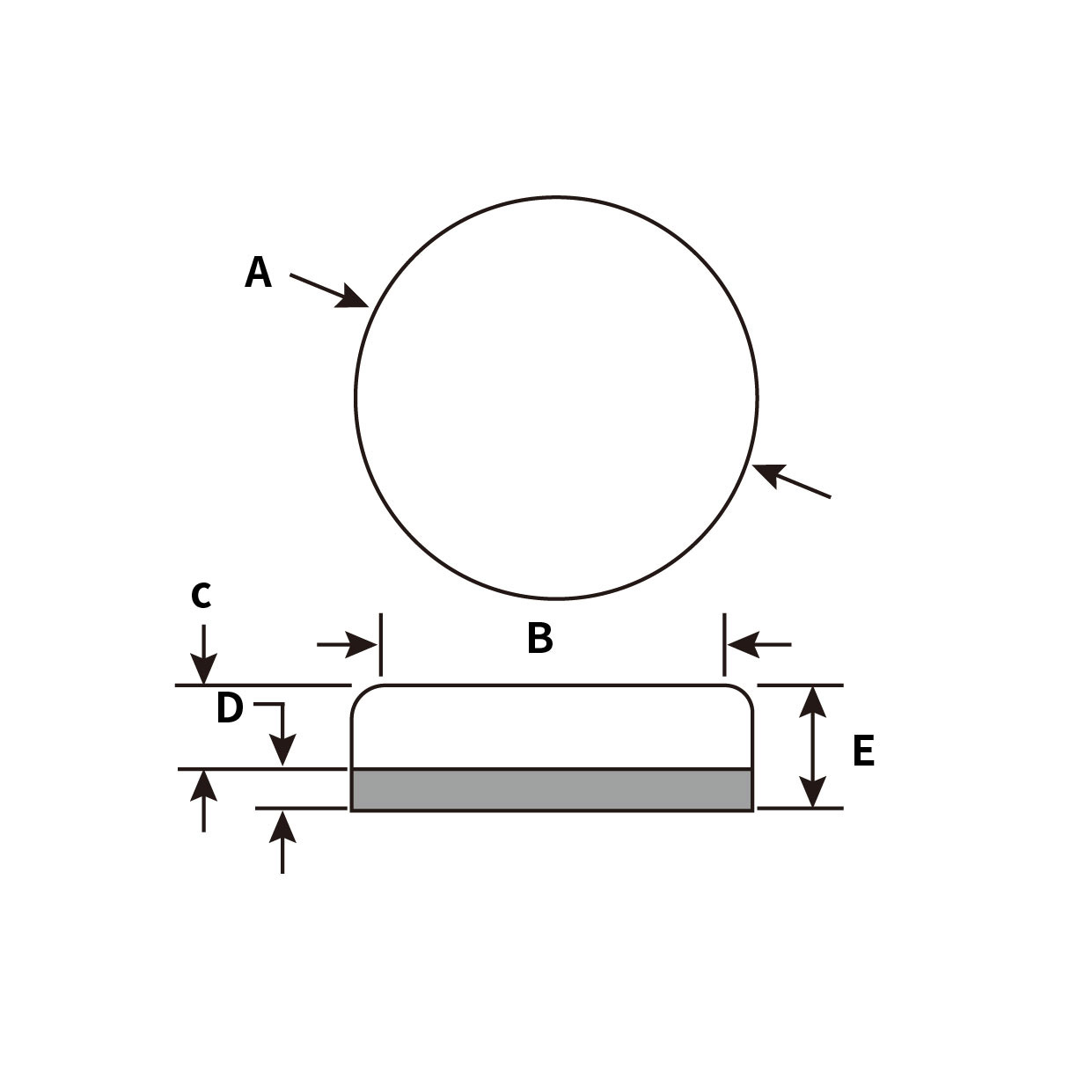

Button / Ring Wear Block

Wear Resistant Casting

Specification

| Part No. | A | B | C | D | E | Weight (kgs) |

| WB60 | 60 | 40 | 20 | 10 | 30 | 0.7 |

| WB75 | 75 | 55 | 20 | 10 | 30 | 1.0 |

| WB75-27 | 75 | 55 | 17 | 10 | 27 | 0.9 |

| WB90 | 90 | 70 | 20 | 10 | 30 | 1.5 |

| WB90-32 | 90 | 70 | 20 | 12 | 32 | 1.6 |

| WB115 | 115 | 95 | 20 | 12 | 32 | 2.6 |

| WB150 | 150 | 130 | 25 | 16 | 41 | 5.7 |

| WB150-32 | 150 | 130 | 20 | 12 | 32 | 4.5 |

Overview

Button wear block: Button wear block is the best choice when wear resistance is required at local or certain points.

Ring wear block: Ring wear block can avoid the concave and convex position of the original machinery, providing wear protection at the concave and convex edge, improving the wear resistance and prolong the service life.

Write your message here and send it to us