WELD OVERLAY WEAR PLATES

Aland offers a range of premium quality weld overlay clad wear plates.

The welded overlay is achieved by advanced welding technology metallurgically bonded to a mild steel backing plates,

forming a protective and durable surface. Different grades of clad overaly are available to suit various working conditions.

Product Advantages

• Hardness of 58-65HRC dispersed evenly

• Consistent microstructure

• Outstanding wear resistance performance

• Wide range for selection

• Industry leading flatness:±3mm/m

• Unmatched formability

• Excellent interface strength

• Customized specification

Product Range

-

ALD100

ALD100 is a clad plate manufactured by welding high chromium,abrasion resistant material to a steel base metal. The overlay material consists of ...

-

ALD200

ALD200 is a complex chromium carbide clad plate manufactured by welding high chromium and Niobium,abrasion resistant material to a steel base metal...

-

ALD300

ALD300 is a complex chromium carbide clad plate manufactured by welding high chromium, heat resistant, abrasion resistant material to a steel base ...

-

ALD600

ALD600 is a customized clad plate manufactured by welding high chromium, complex carbide, abrasion resistant material to a steel base metal. The o...

-

ALD-F

ALD-F is manufactured using advanced fusion bond welding technology to apply chromium carbides on to a mild steel substrate producing consistent ch...

-

ALD-X

ALD-X is a clad plate manufactured by welding much higher chromium,abrasion resistant material to a steel base metal. The overlay material consi...

Working with Aland's wear plates

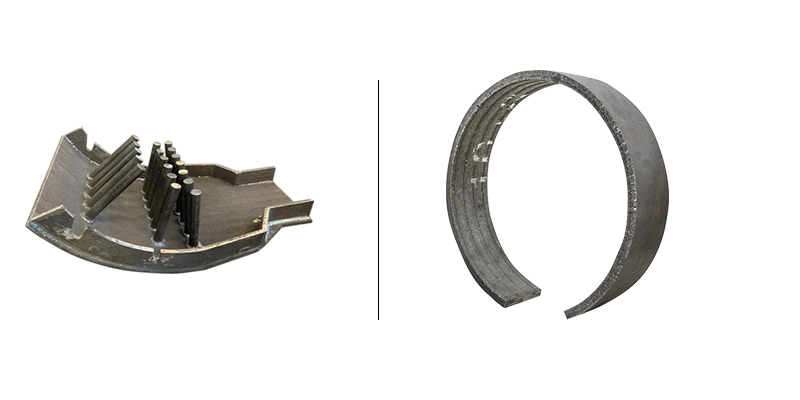

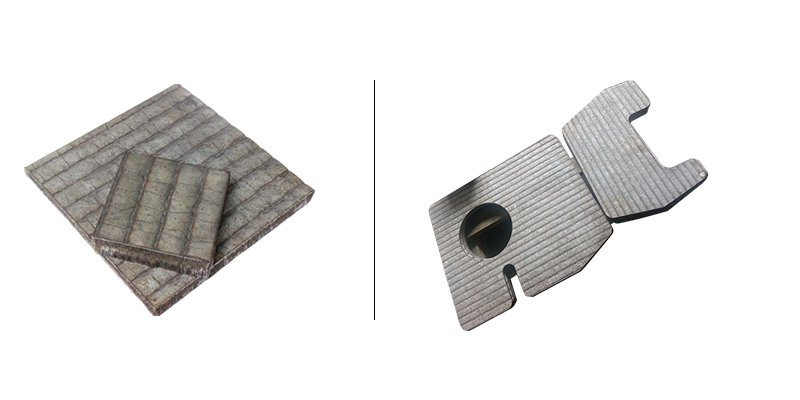

We recommend to use plasma cutting to cut our wear plates. The plates can be easily cold formed into many shapes and ready-to-go wear liners. Below are our main processing methods:

Cutting

Aland overlay plates could be cut only by plasma, waterjet and laser cutting. Plasma cutting is the recommendated method to cut our plates.

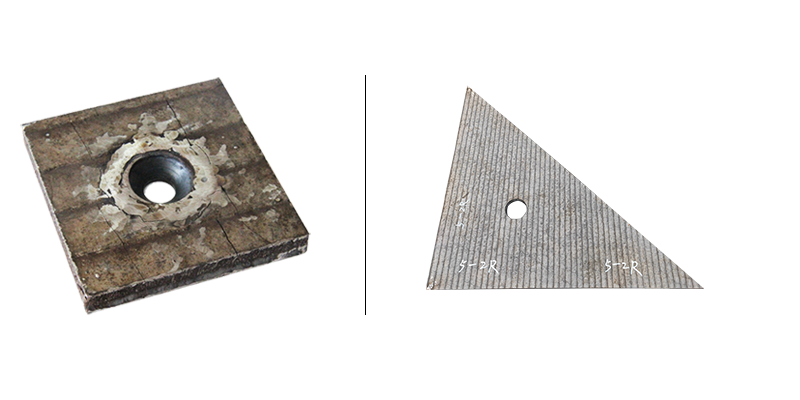

Bores

Liner plate with straight bores can be plug welded to base plates; Liner plate with CSK holes can fit well with bolt studs(M12,M16, M20 etc).

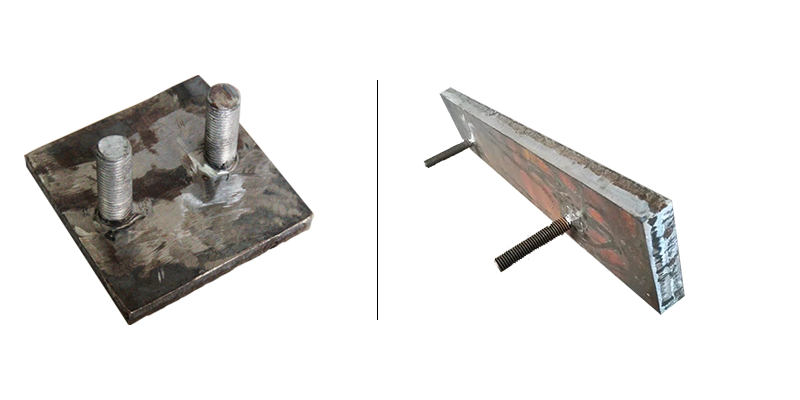

Stud attachment

Our plate can be fabricated with studs welded to backing of wear plate.

Cold bending

Our plates can be cold bended, forming is suggested be perpendicular to the welding bead direction.